In the world of maintenance and construction, brackets play a crucial role, often serving structural and aesthetic purposes. These components can be essential in supporting weight, reinforcing joints, or stabilizing structures like shelves, overhangs, and architectural details. In maintenance, ensuring brackets are in good condition is vital for the safety and longevity of the construction elements they support. This is an important consideration for businesses in the San Ramon, Dublin, Pleasanton, Livermore, and Danville areas.

The concept of painting brackets – especially metal ones – might seem insignificant at first glance. However, it is important to protect the brackets and enhance the overall appearance of a building. It might seem like a small detail in the grand scheme of a construction or maintenance project. However, its impact on the structure’s integrity, longevity, and appearance is substantial. Ignoring such details can lead to premature wear, safety hazards, and potentially higher costs in the long run.

Corrosion is the worst enemy of any metal. Metallic parts of a commercial building can be affected by corrosion, reducing its overall appearance, structural integrity, and value. Painting or coating metal elements, such as brackets, is one of the most effective ways to prevent them from corrosion. This article explores metal brackets in commercial buildings and how painting them is crucial in preventing corrosion and maintaining a commercial building’s overall appearance and structural integrity.

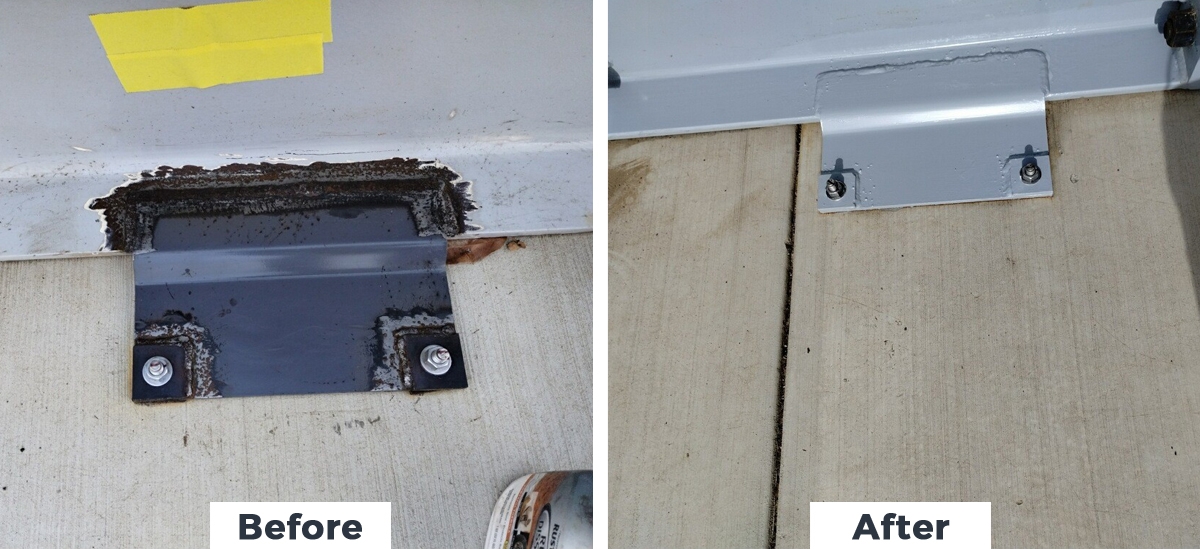

Bracket Painting Project by Custom Painting, Inc.

Custom Painting, Inc. recently finished a bracket painting project in Milpitas, CA. In this project, we painted a total of 76 brackets, which were all horizontal. We are used to this type of project as we do similar work a few times a year, making us a reliable company for this paint job.

1. The painting process

Our crew first primed the brackets using Sherwin Williams Macropoxy 646, a high-solid, high-build, and fast-drying polyamide epoxy designed to protect steel in industrial environments.

For the finishing coat, our crew used the Sherwin Williams Pro Industrial DTM Acrylic, a water-based and corrosion-resistant acrylic coating formulated for interior and exterior applications, to match the adjacent material rails to which the brackets were welded.

The project took two days to complete. The first day was for the prepping and priming, and the second was for applying the finishing coat.

2. Challenges faced

During the project, the weather was the only problem our crew encountered due to frequent rain this time of the year. For this reason, the team had a 4-day window (one day prior, two days for application, and one day following) to complete the work properly. Luckily, the weather cooperated, the team had excellent primer and finish paint adhesion, and the custom color match was perfect.

The role of brackets in commercial construction

1. Definition and types of brackets used in commercial construction

In commercial construction, brackets are significant in providing structural support and integrity to a building’s various elements. Brackets are structural components typically made of metal, wood, or other sturdy materials. They are designed to support loads, distribute weight, and connect different structure parts.

There are several types of brackets used in commercial construction, including:

- L-shaped brackets – These are used to support shelves or as part of framing systems.

- U-shaped brackets – Often used for piping or conduit supports.

- Custom-designed brackets – Tailored for specific structural needs or architectural aesthetics.

2. Examples of bracket applications in structures

Here are some common roles and importance of brackets in commercial construction:

- Supporting loads – Brackets are often used to support heavy loads such as beams, shelves, countertops, or other architectural features. They are strategically placed to bear the weight and transfer it to the building’s framework or supporting structure.

- Connecting elements – Brackets connect different building elements, such as attaching walls to floors or ceilings, joining beams to columns, or securing trusses in place. They provide a strong connection that ensures stability and structural integrity.

- Reinforcement – In areas where additional strength is needed, brackets can reinforce joints or connections. This reinforcement helps prevent structural failure, especially in high-stress areas or during extreme weather conditions.

- Alignment and stability – Brackets help maintain the building components’ alignment and stability. They ensure that elements such as walls, columns, or beams remain in the correct position and resist movement or deformation over time.

- Flexibility in design – Brackets offer architects and engineers flexibility in design by providing options for supporting various building configurations and layouts. They allow for creative architectural features while ensuring structural stability and safety.

- Ease of installation – Brackets are relatively easy to install, saving time and labor costs during construction. They can be prefabricated off-site and installed quickly at the construction site, contributing to efficient project completion.

- Aesthetic considerations – While primarily functional, brackets can also contribute to the aesthetic appeal of a building. They come in various shapes, sizes, and finishes, allowing designers to incorporate them as decorative elements that complement the overall architectural style.

1. The importance of brackets in ensuring structural integrity

Brackets are essential in commercial construction as they are vital to ensure the buildings’ structural integrity, safety, and longevity. Properly designed and installed brackets help distribute loads, reinforce connections, and maintain stability, ultimately contributing to a durable and reliable built environment.

What is corrosion, and how can it affect metal brackets?

Corrosion is a natural process when metals react with their environment, gradually deteriorating due to chemical or electrochemical reactions with substances like oxygen, water, acids, or salts. This process typically degrades the metal’s properties, such as strength, appearance, and functionality.

Corrosion can occur in various forms, including rusting (oxidation of iron and steel), tarnishing (formation of a thin layer on the surface of metals like silver and copper), and pitting (localized corrosion resulting in small holes or craters). It is a significant concern in various industries, including construction, transportation, manufacturing, and infrastructure, as it can lead to structural failures, increased maintenance costs, and safety hazards.

Corrosion can have several detrimental effects on metal brackets used in construction:

- Structural integrity – Corrosion weakens the metal, compromising its structural integrity. It can lead to the failure of the brackets, causing collapse or instability in the structure they support.

- Reduced load-bearing capacity – As corrosion progresses, the metal brackets lose material and strength, reducing their load-bearing capacity. It can overload other structural components or systems, causing further damage or collapse.

- Aesthetic degradation – Corrosion often manifests as rust or other forms of surface degradation, which can negatively impact the aesthetic appearance of the construction project. This factor is particularly significant in architectural applications where visual appeal is important.

- Safety risks – Corrosion can create sharp edges or protrusions on the surface of metal brackets, increasing the risk of injury to construction workers or occupants of the building.

- Long-term maintenance costs – Addressing corrosion requires maintenance and repair efforts, which can incur significant expenses over the lifespan of a structure. Failure to adequately address corrosion can lead to more extensive damage and higher repair costs in the future.

- Serviceability concerns — Corrosion can impede the proper functioning of mechanical systems or components attached to the metal brackets, such as piping or electrical conduits. It can result in serviceability issues and operational disruptions.

Preventive measures such as coatings, corrosion-resistant materials, and proper maintenance practices are often employed to mitigate corrosion and extend the lifespan of metal components and structures.

The purpose of painting brackets

Painting brackets, particularly in construction or engineering contexts, serves several purposes:

- Identification – Brackets are often painted to help identify them during installation or maintenance. Different colors may distinguish between brackets of various sizes, shapes, or functions.

- Protection – Painting brackets can provide a protective layer against corrosion, rust, and other forms of degradation, particularly in outdoor or harsh environments. The paint acts as a barrier, preventing moisture and other corrosive elements from reaching the metal surface of the bracket.

- Aesthetic appeal – In some cases, brackets may be painted for aesthetic reasons, especially if they are visible in the final structure or if the project requires a specific design or color scheme.

- Safety – Painting bright or reflective-colored brackets can enhance safety by making them more visible, reducing the risk of accidents or collisions, particularly in industrial settings where heavy machinery is in use.

Painting brackets helps improve their longevity, functionality, and visibility, contributing to the overall quality and safety of the structure or system in which they are used.

The benefits of painting brackets

Painting brackets in commercial construction can offer several benefits, including:

- Aesthetic appeal – Painting brackets can enhance the overall appearance of the building. It allows for customization to match the desired color scheme or architectural style, contributing to the overall aesthetic appeal of the structure.

- Corrosion protection – Painting brackets can act as a protective barrier against corrosion, especially in outdoor or exposed environments where brackets are subject to weathering elements such as rain, snow, and humidity. The paint acts as a shield, preventing moisture and other corrosive substances from coming into direct contact with the metal, thus extending the lifespan of the brackets.

- Durability – Painted brackets are often more durable and resistant to scratches, abrasions, and other forms of damage than unpainted ones. This increased durability can lead to longer-lasting brackets, reducing the need for frequent maintenance or replacement.

- Identification and safety – Painting brackets in distinctive colors can aid identification, particularly in large-scale commercial construction projects where numerous brackets may be installed. Different colors can signify different functions or indicate specific areas, which can benefit maintenance, repair, or safety purposes.

- Enhanced visibility – Painting brackets with high-visibility colors can improve safety by making them more visible to workers and pedestrians, especially in low-light conditions or areas with high foot traffic. It can help prevent accidents and improve overall site safety.

- Compliance – In some cases, painting brackets may be necessary to comply with building codes or regulations. For example, certain fire safety codes may require specific colors or coatings for structural elements to indicate fire-resistant properties or emergency exits.

- Brand image – For commercial properties, painting brackets in branded colors or with company logos can help reinforce brand identity and create a cohesive visual impression for visitors and clients.

Painting brackets in commercial construction offers numerous benefits, from aesthetic improvements to increased durability and safety enhancements.

The challenges of painting brackets

Painting metal brackets in construction can present several challenges. Here are some common ones:

- Surface preparation – Proper surface preparation ensures the paint adheres well and provides a smooth finish. Depending on the material of the brackets, this may involve cleaning, sanding, priming, or using a special etching solution.

- Access – Brackets are often installed in tight or hard-to-reach spaces, making it challenging to paint them thoroughly and evenly. It can require creative solutions or disassembly of the brackets for painting.

- Uniform coverage – Achieving consistent coverage can be challenging, especially on intricate or detailed brackets with numerous angles and curves. Multiple coats of paint may be necessary to achieve the desired finish.

- Drying time – Proper drying time between coats is crucial to prevent drips, sags, and uneven coverage. Limited space or environmental conditions such as high humidity can extend drying times, requiring patience and careful planning.

- Paint selection – Choosing the right type of paint is important for durability and compatibility with the bracket material. Consider some factors, including indoor or outdoor use, exposure to elements, and whether a primer or sealer is needed.

- Color matching – Ensuring color consistency with existing elements can be challenging if the brackets are part of a larger structure or decor. It may involve custom color mixing or precise selection from available paint options.

- Durability – Brackets may be subject to wear and tear, impacts, and exposure to weather or corrosive elements. Selecting a paint that protects adequately against these factors is essential for longevity.

- Safety precautions – When painting brackets in situ, you should take some precautions to protect surrounding surfaces, furniture, and flooring from paint splatter or spills. Additionally, you should wear appropriate safety gear, such as gloves, goggles, and masks, as needed.

- Aesthetics – While functionality is paramount, ensuring the painted brackets complement the overall aesthetic of the space or structure is also crucial. It may involve coordinating with other design elements or finishes.

- Maintenance – Proper maintenance is necessary to preserve the appearance and functionality of painted brackets over time. It may include periodic touch-ups or recoating as needed and regular cleaning to remove dirt, dust, or grime.

Best practices for painting brackets

Painting metal construction brackets can help protect them from corrosion and enhance their appearance. Here are some best practices to follow when painting metal brackets:

- Surface preparation – Proper surface preparation is essential for a successful paint job. Clean the brackets thoroughly to remove any dirt, grease, or rust. Then, use a degreaser and a wire brush or sandpaper to remove rust and slightly roughen the surface for better paint adhesion.

- Priming – Apply a primer specifically designed for metal surfaces. The primer will help the paint adhere better and provide additional protection against corrosion. Make sure to choose a primer suitable for the type of metal you’re painting.

- Choosing paint – Select a high-quality paint suitable for metal surfaces. Consider using spray paint for even coverage and a smooth finish. Look for paints suitable for metal and outdoor use to ensure durability and weather resistance.

- Application technique – When applying the paint, use smooth, even strokes to achieve uniform coverage. Hold the spray can or paintbrush consistently from the surface to avoid drips or uneven application. Apply multiple thin coats rather than one thick coat to prevent runs and ensure thorough coverage.

- Drying time – Allow sufficient drying time between coats per the paint can’s instructions. Avoid handling or disturbing the brackets until the paint is completely dry to prevent smudges or imperfections.

- Protective finish – Consider applying a clear topcoat or sealant over the painted surface to protect against UV rays, moisture, and abrasion. This step is particularly crucial for outdoor applications to prolong the lifespan of the paint job.

- Safety precautions – When painting, work in a well-ventilated area to avoid inhaling fumes. Wear appropriate safety gear, such as gloves and a mask, to protect yourself from chemical exposure.

- Maintenance – Regular maintenance can help extend the life of the painted brackets. Inspect them periodically for signs of wear or damage. Touch up any areas where the paint has chipped or peeled to prevent corrosion.

Recommendations for paint types and protective coatings

1. Primer

Start with a good primer to ensure proper paint adhesion to the bracket’s surface. Look for a primer suitable for the material of your brackets, such as metal primer for metal brackets or wood primer for wooden brackets.

2. Paint type

For metal brackets, consider using enamel or epoxy-based paint. These paints provide excellent durability and resistance to corrosion, making them ideal for outdoor or high-moisture environments. Additionally, powder coating is a popular choice for metal brackets, providing a tough, long-lasting finish.

3. Finish

- Glossy finish – Provides a shiny, reflective surface that is easy to clean and protects well against moisture and stains.

- Satin finish – Offers a subtle sheen that is less reflective than glossy finishes but still provides some level of protection against moisture and stains.

- Matte finish – Provides a flat, non-reflective surface that can hide imperfections well. Matte finishes are less durable than glossy or satin finishes. However, it still can offer adequate protection with protective coatings.

4. Protective coatings

- Clear coat – Apply a clear coat over the painted surface to protect against UV rays, moisture, and abrasion. Clear coats are available in various finishes, including glossy, satin, and matte.

- Rust inhibitors – Consider using a rust inhibitor as a protective coating for metal brackets, especially if the brackets will be exposed to moisture or harsh weather conditions.

5. Application method – Depending on your preference and the size of the brackets, you can apply the paint and protective coatings using brushes, rollers, or spray guns. Ensure proper ventilation and follow the manufacturer’s application and drying times instructions.

Maintenance and inspection

- Regular inspections – Inspect painted brackets for signs of wear, such as chipping, cracking, or fading. Early detection of issues allows for prompt touch-ups, extending the paint job’s life.

- Touch-up as needed – Do touch-ups on damaged areas as soon as possible to prevent corrosion and maintain the protective barrier.

- Record keeping – Maintain records of paint types, colors, and application dates for each set of brackets. This information can be invaluable for maintenance planning and ensuring consistency in touch-ups or repaints.

By following these best practices, using the appropriate paints or coatings, and performing regular maintenance, you can achieve a professional-looking paint finish on metal construction brackets that enhances their appearance and provides long-lasting protection against the elements.

Conclusion

Corrosion poses significant challenges for commercial buildings, ranging from structural durability and functional performance to aesthetic appeal and maintenance costs. It can have several detrimental effects on metal brackets used in constructing commercial buildings.

Various protective measures can be implemented to mitigate the effects of corrosion, such as using corrosion-resistant materials and applying protective coatings. Regular inspections and maintenance are also essential to promptly identify and address corrosion issues.

The long-term advantages of investing in painting metal brackets go far beyond the immediate visual appeal, as it also protects them from corrosion. This can also be true for example of maintaining rusty metal doors. This proactive approach ensures the commercial buildings’ structural integrity and contributes to reduced maintenance costs and increased property value over time.

Make painting and maintaining metal brackets a priority by contacting Custom Painting, Inc., and discover the long-term benefits of investing in quality custom paint service. If you would like a free paint estimate for interior or exterior painting for your home or commercial building, or if you have questions about painting and renovations, call us at 925-866-9610. You can also use our contact form, and we will get back to you.